Instantly Experience Feasibility You Can Defend

Optioneering without the guesswork

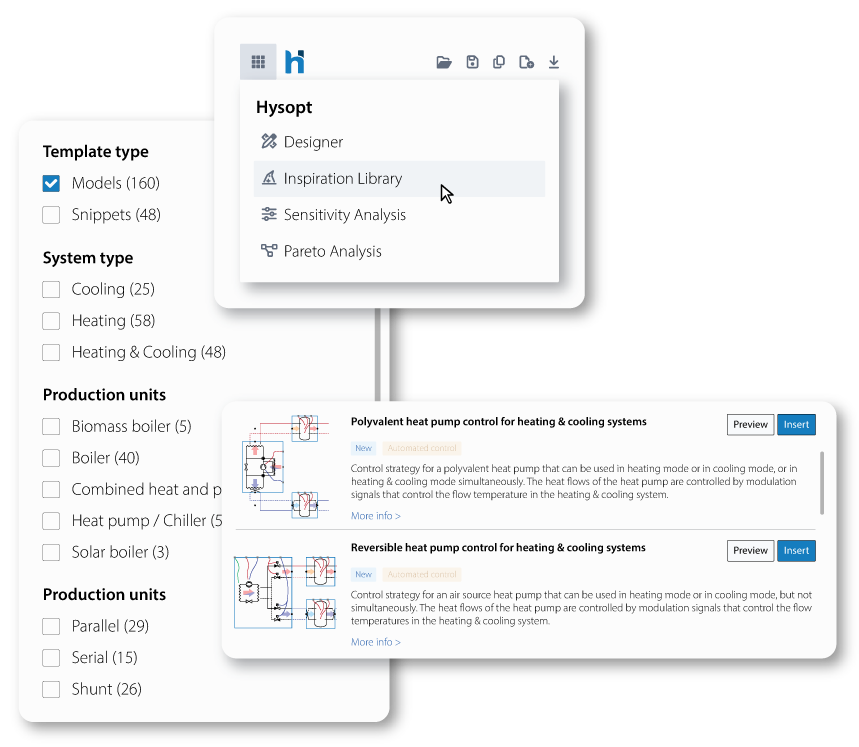

Bid phases and feasibility studies don’t allow weeks of modelling. In one focused session we’ll build template‑based variants from the 160 Concept Template Library and compare Opex, Capex, Carbon and asset sizes (e.g., heat‑pump capacity, buffer vessel volume) on a single defendable page.

Book a time to see Hysopt Feasibility in action

- Decide early: Go/no‑go based on physics, not rules of thumb.

- Compare cleanly: Standardised Opex / Capex / Carbon views across variants.

- Right‑size production assets: Test HP capacity, buffer volume, ΔT and control concepts.

- Ready to submit: Walk away with a Feasibility Pack for tender, decarb, or subsidy cases.

Industry leaders trust Hysopt for feasibility

What M&E teams get out of it

- Faster bid qualification with evidence you can show clients.

- Consistent outputs (no spreadsheet drift) you can reuse on the next project.

- Fewer late surprises from hydraulic and control issues spotted early.

- Clearer trade‑offs between energy, cost, carbon and comfort.

.webp?width=2000&height=1189&name=6600203a13d5a8d681dd6e96_proven-concepts-library%20(2).webp)

Standardise Feasibility Across Your Organisation

Most consultancies rely on individual engineers’ experience to run feasibilities — meaning speed, quality, and consistency vary.

With Hysopt Feasibility, every team can work from the same validated concepts, KPI structure, and workflows.

-

Templates for every building type. 160+ proven concepts ready to adapt.

-

Consistent evidence base. Comparable results across bids and regions.

-

Less dependency on senior engineers. New team members get up to speed faster.

-

Reusable setups. Once built, a feasibility model can be cloned and re-run in minutes.

Turn your feasibility process into a repeatable advantage.

.png?width=1920&height=1000&name=Testimonial%20-%20Dennis%20Hofmann%20-%20Schermer%20Installatietechniek%20(1).png)

Ready to objectify feasibility in 1–2 hours?

Training included • Templates reusable • No BIM required for feasibility

Still Have Questions?

Do we need BIM to participate?

No. We can run feasibility from templates and key inputs; BIM helps later but isn’t required here.

Is “1–2 hours” realistic?

Yes—because we limit the workflow to feasibility, start from concept templates, and focus on the exact features needed to produce a defendable comparison in a single session.

How is this different from Designer or Simulator alone?

This is a wrapper that uses Designer + Simulator under the hood but narrows training and templates to feasibility, so you get to a decision‑ready output quickly.

What data should we bring?

Building type, indicative loads or metered history, operating hours, supply/return temps & ΔT, known constraints (grid limit, plant space), and any client KPI targets (Opex / Capex / CO₂).

Where is this most useful?

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Nullam tempor arcu non commodo elementum.